Application: mining, smelting, building materials, highway, railway, water conservancy and chemical industry and many other industries. Processing materials: limestone, granite, marble, basalt, iron ore, pebble, shale, bluestone, coal, pebble, construction waste, etc.

1. Fully automatic crushing control system, quick response to iron (overload) automatic release reset protection, wireless remote control operation, can reduce equipment operators, to ensure continuous, stable and efficient production.

2. Use the lamination crushing principle to crush the material, high crushing efficiency, low wear of wearing parts. After crushing, the finished product is cube with high fine content, which can meet the use needs of some high-quality aggregates.

3. The thin oil lubrication system adopts redundant design of double oil pump and double filter, which can be lubricated before the equipment is started. It has strong adaptability and easy control, and prolongs the service life of parts.

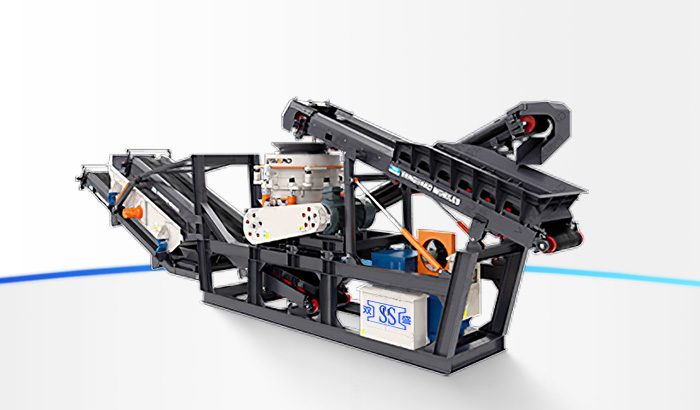

MBP SERIES CONICAL crushing station is equipped with excellent performance and suitable for medium and fine crushing cone crusher, special crushing wall and rolling mortar wall design, complemented by curve cavity type and hydraulic cavity cleaning system, which can effectively improve the crushing efficiency and effectively reduce easy operation loss.

| Project | Device name | Model and Specification | Power (kW) | Quantity (set) | |

| HP300Cone break | Cone break | Equipment | HP300 | / | 1 |

| + | Triangle | Standard | / | 7 | |

| 1542Returned to the screen | Motor | Standard | 250 | 1 |

| Returned to the screen | Equipment | 1542 | / | 1 | |

| Vibration motor | Standard | 3.7 | 2 | ||

| Modular steel construction | Standard | / | 1 | ||

| Feeding conveyer | Specifications | B1000*6m | 7.5 | 1 | |

| Drive way | Electric drum drive | / | 1 | ||

| Main conveyor | Specifications | B1000*8.7m | 7.5 | 1 | |

| Drive way | Electric drum drive | / | 1 | ||

| Screen down conveyer | Specifications | B1200*6.2m | 7.5 | 1 | |

| Drive way | Electric drum drive | / | 1 | ||

| Transfer conveyer | Specifications | B650*2m | 3 | 1 | |

| Drive way | Electric drum drive | / | 1 | ||

| Return material conveyor | Specifications | B500*9.5m | 5.5 | 1 | |

| Drive way | Electric drum drive | / | 1 | ||

| Electrical system | Electric control cabinet | Main engine soft start, electrical components Chint | / | 1Set of | |

| Folding oil cylinder of belt conveyor | / | 1Set of | |||

| Hydraulic pump, valve, station and tubing accessories | / | 1Set of | |||

| Total power288.4KW | |||||