Application: Mining, metallurgy, construction, highway, railway, water conservancy, chemical industry, etc. Processing materials: granite, marble, basalt, iron ore, pebbles, shale, bluestone, coal, pebbles, building materials, etc.

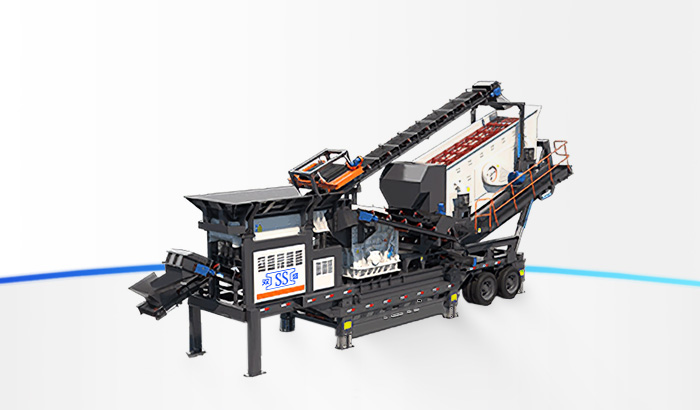

1. The combined mobile station greatly expands the conceptual field of coarse crushing and fine crushing. Its design principle is standing in customer's position, eliminate the broken area, the environment, multifarious basic configuration gives customers crushing operation, flexible configuration according to the requirements of different customers primary crushing, and optimize the crushing screening combination, since the carrier contains conveying screening, largely meet customers personalized needs of the scene.

2. The combined mobile station is a better choice for the customer site with small and medium output demand, frequent mobile working environment and independent stone production.

3. The legs of the car body can be flexibly telescoped according to the height of the ground to ensure the stability of the car body and prolong the service life of the equipment when the machine is operating.

For the demand of small and medium output, often moving the working environment and independently completing the customer's demand of stone production, VPM-3 combined mobile crushing station is a good choice, which can be used for the operation of mobile stone in highways, railways, hydropower projects and other projects, breaking the limitation of small crushing site. Users can according to the type of processing raw materials, Different scale and finished material requirements adopt a variety of configuration forms, greatly reduce the investment cost, while improving the investment income.

| Equipment model | VPM-3 PCZ1310 | VPM-3 PCZ1510 | VPM-3 PE57 | VPM-3 PE69 | VPM-3 CSV110 | VPM-3 CSV132 |

| Feed particle size (mm) | ≤400 | ≤750 | ≤425 | ≤500 | ≤160 | ≤180 |

| Production capacity (t/h) | 120-380 | 250-320 | 45-100 | 60-160 | 50-235 | 60-260 |

| Equipment model | VPM-3 FX1010 | VPM-3 FX1210 | VPM-3 FX1214 | VPM-3 FX1315 | VPM3 LF150 | VPM3 LF250 |

| Feed particle size (mm) | ≤500 | ≤600 | ≤600 | ≤700 | ≤550 | ≤600 |

| Production capacity (t/h) | 70-150 | 100-285 | 150-400 | 180-500 | 100-200 | 200-400 |