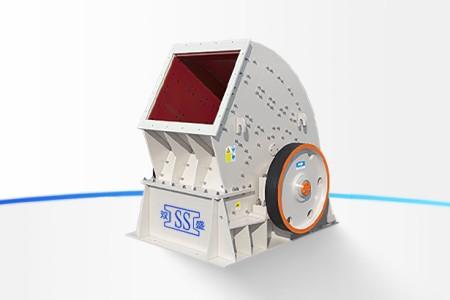

1.Application Scope: Suitable for mining, cement, coal, metallurgy, building materials, highway, combustion and other departments of medium medium hardness and brittle materials for fine crushing. 2.Processing materials: granite, limestone, concrete, etc.

The feeding port can reach 1600mm, and the output can reach 3000 tons at high time. The crushing chamber design conforms to the dynamic principle, increases the amount of material through, solves the problem of hammer breaking and blocking, and can crush wet materials. Compared with similar products, the output is increased by 30%.

On the mechanical principle of common hammer crusher, impact crusher, vertical shaft hammer crusher and all kinds of hammer head (plate hammer) to hit and break stone, combined with more than 30 years of stone crushing experience, the design of heavy hammer impact crusher.

The all-in-one crushing and shaping machine, with large input particle size, adjustable discharge particle size, reasonable gradation of finished materials, material type in line with the standard of building materials, changes the three-stage crushing to one-stage crushing, one broken molding, no need for two broken, reducing 35% of the equipment investment.

The working principle of

The heavy hammer crusher is broken by the impact of the high speed slewing hammer. Hammer crusher can be divided into single rotor and double rotor hammer crusher. Single rotor hammer crusher hammer head of articulated high-speed operation, while working to give into the large materials, and make it into the body wall bearing strike plate material after further impact crushing, rested on the following article Bi, granularity of qualified product from a crack in the article Bi exclusion, Bi bar materials continue to hammer blow, extrusion, grinding, until all through the article Bi position.

|

型号 |

rotor diameter(mm) |

Feed port size(mm) |

Feed particle size(mm) |

Processing power (t/h) |

Motor power(KW) |

Overall dimensions Length x width x height(mm) |

| PCZ1308 | 1310×790 | 850×800 | ≤600 | 100-160 | 132 | 2818×2100×2390 |

| PCZ1510 | 1500×900 | 1000×900 | ≤700 | 160-210 | 132×2 | 3260×2414×2750 |

| PCZ1512 | 1500×1160 | 1200×900 | ≤750 | 250-320 | 160×2 | 3260×2624×2750 |

| PCZ1615 | 1650×1452 | 1500×1200 | ≤1000 | 360-420 | 200×2 | 3456×2915×3185 |

| PCZ1620 | 1660×1900 | 2000×1200 | ≤1200 | 800-1000 | 315×2 | 3500×3100×3200 |

| PCZ1820 | 1800×1964 | 2000×1200 | ≤1200 | 1000-1200 | 450×2 | 3270×3210×3520 |

|

Model |

Rotor diameter(mm) |

Feed port size(mm) |

Feed particle size(mm) |

Processing power (t/h) |

Motor power(KW) |

Overall dimensions Length x width x height(mm) |

| XPC0706 | 700×750 | 618×510 | ≤400 | 50-70 | 75 | 1950×1340×1480 |

| XPC0808 | 800×750 | 780×610 | ≤500 | 80-100 | 132 | 2280×1790×1670 |

| XPC0910 | 900×1000 | 1070×750 | ≤600 | 150-200 | 110×2 | 2600×2200×1940 |

| XPC1012 | 1000×1180 | 1255×810 | ≤650 | 250-300 | 132×2 | 2800×2310×2210 |

| XPC1213 | 1200×1280 | 1350×900 | ≤750 | 300-350 | 160×2 | 2970×2580×2510 |

| XPC1216 | 1270×1490 | 1530×920 | ≤750 | 400-500 | 200×2 | 3070×2840×2580 |

| XPC1220 | 1220×1950 | 2000×920 | ≤750 | 500-600 | 220×2 | 3080×3380×2580 |