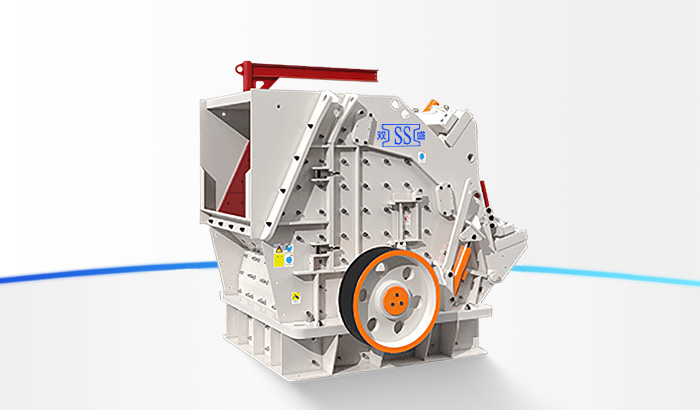

By adjusting the installation position of counterattack frame, it can realize the conversion of coarse crushing and medium crushing, one machine and two uses. Plate hammer selection of high wear resistant material, long service life, C-type design, change the Angle of impact, high crushing efficiency, simple and reliable plate hammer locking, easy to replace and install. Larger inlet, coarse crushing can be initially broken use, the larger feed to 1000mm.

The working principle of

This machine is a kind of crushing machine that uses impact energy to break materials. When the material enters the plate hammer action zone, it is broken by the high speed impact of the plate hammer, and is thrown to the counter device installed above the rotor and broken again, and then bounced back to the plate hammer action zone by the counter lining plate and broken again. This process is repeated until the material is broken to the desired size and discharged from the lower part of the machine. Adjusting the clearance between the counter frame and the rotor can achieve the purpose of changing the material size and shape. The machine adopts spring safety device after counterattack. When the non-broken material enters the crushing cavity, the front and rear counterattack frame will retreat, and the non-broken material will be discharged from the machine.

- Multi-purpose machine

By adjusting the installation position of the counterattack frame, the conversion of coarse crushing and medium and fine crushing can be realized, and one machine can be used for two purposes.

- Large feed up to 1000MM

The feeding port is larger, and it can be used for initial crushing, and the maximum feeding is 1000mm.

-Anti-rebar wrapping function

When crushing construction waste, it can effectively prevent steel bars from entanglement.

- High crushing efficiency

The blow hammer is made of high wear-resistant materials, with a long service life. It adopts a C-shaped design, which can change the striking angle and has high crushing efficiency. The locking of the blow hammer is simple and reliable, and it is easy to replace and install.

- Low maintenance cost

The key components are highly interchangeable, effectively prolonging the service life of consumables, and the use of maintenance brackets greatly reduces labor intensity.

|

Model |

Feed opening size(mm) |

Max Input size(mm) |

Processing Capacity(t/h) |

Power(kw) |

Weight(kg) |

|

LF150 |

820*980 |

100-200 |

100-200 |

90-200 |

12000 |

|

LF250 |

960*1360 |

200-400 |

200-400 |

180-250 |

17000 |

|

LF350 |

1050*1700 |

300-500 |

300-500 |

200-400 |

24000 |